M2.1 | Optimisation of novel vanadium based high temperature materials

Funding period: Aug 2017 to Jul 2021

Researcher: Christopher Müller

Wrap-up

Keywords: Vanadium-Based Alloys, Microstructure-Property-Relationship, Intermetallics, V-Si-B-X, Vanadium Solid Solution Phase

Background:

Due to the low density in combination with a high melting point, vanadium demonstrates a great lightweight potential for turbines in aircrafts or energy industry. Since vanadium as a structural material is in focus of research only recently, the effects of several alloying elements on the materials properties are not or insufficiently examined yet.

Objective:

The investigation of the microstructure-property relationship in binary, ternary and quaternary V-based alloys in order to use the findings to improve high-temperature alloys based on V-Si-B.

Methods:

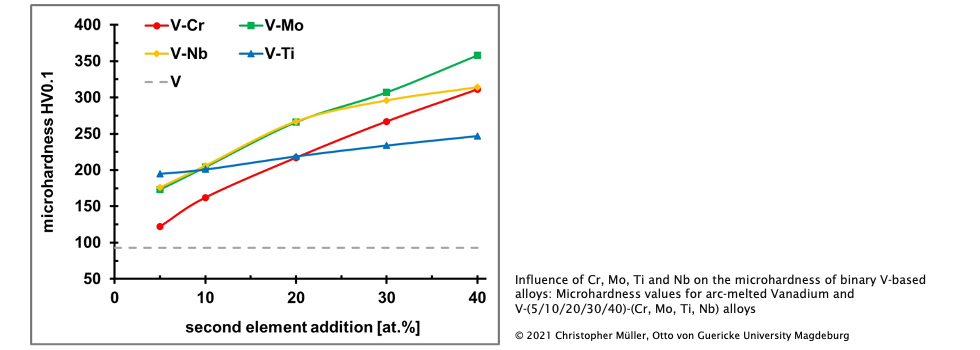

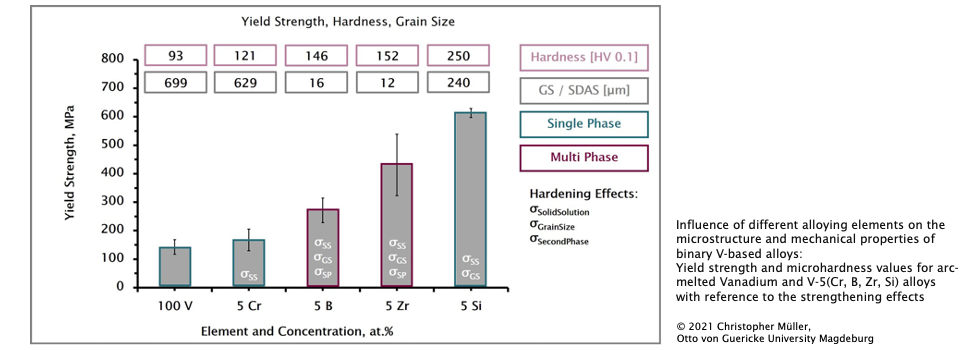

By means of ingot metallurgy (arc-melting process), vanadium samples with different concentrations of alloying elements were manufactured. Resulting from this, single phase vanadium solid solutions (Vss), two-phase and three-phase alloys were produced. Microhardness measurements and compression tests were carried out to determine the mechanical properties in dependence on the alloying components. SEM (Scanning Electron Microscopy) and XRD (X-ray Diffraction) methods were used to examine the microstructure, to identify phases and to measure elements concentration in the respective phases.

Results:

The combination between mechanical characteristics and microstructural investigations enables conclusions concerning the materials behavior and the efficiency of solid solution strengthening and second phase strengthening.

Conclusions:

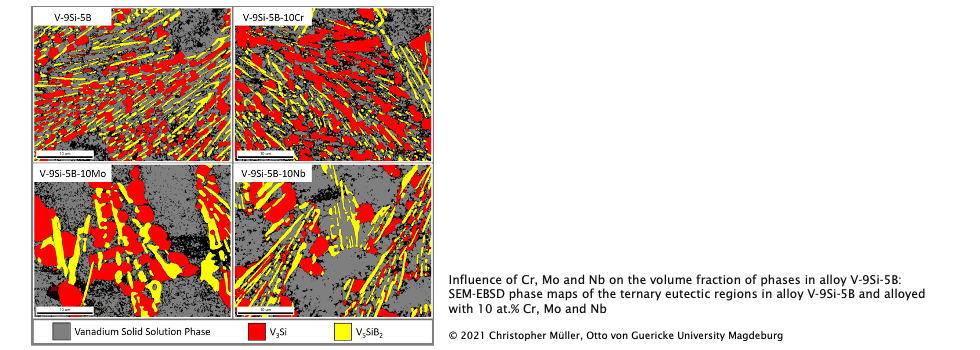

The elements Cr, Mo and Nb have a high potential for improving the microstructure property relationship in modern V-Si-B alloys.

Originality:

Basic research on the effects of various alloying elements in vanadium solid solution, as well as in promising ternary V-Si-B high temperature alloys.